Dealing with the weather

With the nights drawing in and the weather getting worse, it’s a suitable time to get on with the parts of the car that will protect me from the wind and wet.

The water connections on the standard heater clashed with the location of my fuel supply to the carb, so I took the heater apart and swapped the matrix round so that they exit on the other side.

The windscreen is a very curvy item that needs to fit onto a curvy section of the bodywork. Reliable reference points are hard to come by, so there was an awful lot of chin-scratching and trial-and-error involved in figuring out exactly where it needed to sit. It definitely helped having some friends on hand for this job! Eventually we figured out that the scuttle frame needed to be moved a few millimetres to the nearside.

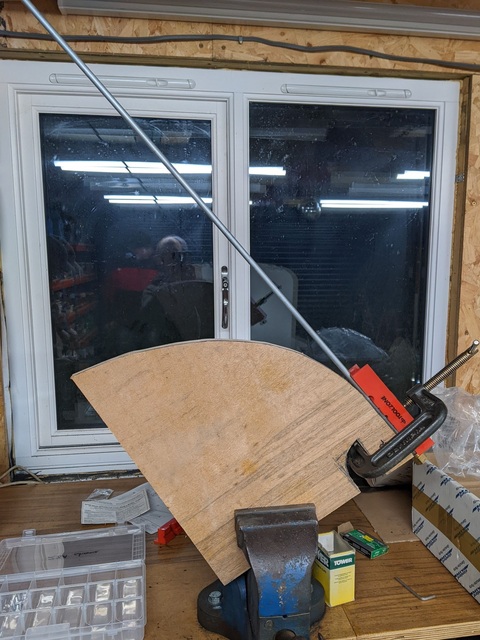

Also it didn’t help that the windscreen had a bit of a twist to it. This is what happens when you enlist the help of a carpenter to sort all of that out!

It took quite a bit of searching but I eventually found a windscreen washer tank that would fit in the remaining space in the engine bay. It’s a bit on the shiny side for my liking, but seems pretty robust.

The inner wing where the tank is to be fitted is far from vertical and there’s no way a standard bracket will do the job, so this seemed like a great time to dig out some spare bits of steel and get cutting and welding. The steel happened to be relatively thick, so the end result is probably strong enough to hold the weight of the whole car, let alone a small water tank!

The tank nestled up at the front of the engine bay.

The recommended location for the wiper motor, and the location the loom is set up for, is behind the dashboard. I don’t have room there, so I’ve decided to place it on top of the passenger footwell instead. Given wiper motors can be somewhat noisy I think that’s where I would rather have it anyway.

To avoid making a large hole in the bulkhead I chopped off the plug for the wiper motor, pushed the wires through the small grommet, and then re-soldered the wires onto the plug inside the engine bay.

The location of the wiper motor requires a gentle bend in the bundy tube.

With the location of the windscreen finalised it was possible to cut and fit the demister vents, fit and plumb in the windscreen washers, and fit the wheelboxes.

The final step was to fit the bundy tube and connect up the vents.